FDA EUA Instruction - EN 149:2001+A1:2009

FFP2 NR E-300 / FFP2 NR E-680 / FFP2 NR 952 / FFP2 NR F-820

Failure to follow all instructions and limitations on the use of these respirators and/or failure to wear these respirators during all times of exposure can reduce effectiveness and may result in sickness or death. For additional information please contact us at https://www.acewiper..com/ or call +86-0769-82329088

These particulate respirators are designed to protect against solid and non-volatile liquid particles.

1. These respirators meet the requirements of EN 149:2001 +A1:2009, filtering facepiece respirators for use against particles. They should be used to protect the wearer from solid and non-volatile liquid particles only.

2. Proper selection, training, use and appropriate maintenance are essential in order for the respirator to help protect the wearer from certain airborne contaminants. Failure to follow all instructions on the use of these respiratory protection and/or failure to properly wear the complete respirator during all periods of exposure may adversely affect the wearer’s health, lead to severe or life threatening illness or permanent disability.

3. Always check that the respirator is within the stated shelf life(use by date).

4. Before use, the wearer must be trained in use of the complete respirator in accordance with Health and Safety standards/guidance.

5. These respirators do not contain components made from natural rubber latex.

6. These respirators do not protect against gases/vapors.

7. Not to be used on children.

8. Do not use in atmospheres containing less than 19.5% oxygen.

9. Do not use for respiratory protection against atmospheric contaminants/concentrations which are unknown or immediately dangerous to life and health (IDLH).

10. Do not use with beards or other facial hair may inhibit contact between the face and the respirator thus preventing a good seal.

11. Leave the contaminated area immediately if:

a) Breathing becomes difficult.

b) Dizziness or other distress occurs.

12. Always be sure you are using the complete respirator.

13. The respirator is suitable for application.

14. The respirator is worn during all periods of exposure.

15. Replace respirator when necessary.

16. Discard and replace the respirator if it becomes damaged, breathing resistance becomes excessive or at the end of the shift.

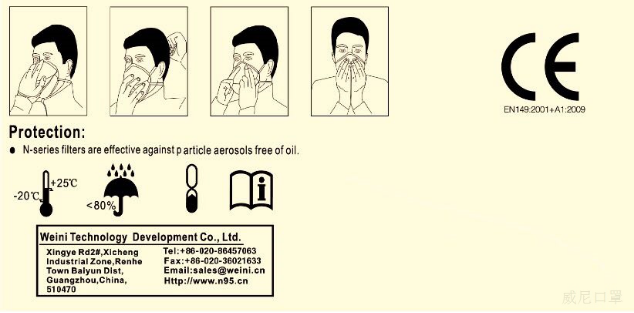

1. Cover the front of the respirator with both hands being careful not to disturb the fit of the respirator.

2. For UNVALVED respirator - EXHALE sharply.

3. For VALVED respirator - INHALE sharply.

4. If air leaks around the nose, re-adjust the nose clip to eliminate leakage. Repeat the above fit check.

5. If air leaks at the respirator edges, work the strap bank along the sides of the head to eliminate leakage. Repeat the above fit check.

If you CANNOT achieve a proper fit, DO NOT enter the hazardous area

All respirator components should be inspected for damage prior to each use.

1. Cup respirator in one hand with nosepiece at fingertips, allow headbands to hang freely below the hand.

2. Hold respirator under chin, with nosepiece up.

3. Locate the upper strap across the crown of the head and the lower strap below the ears.

4. Straps must not be twisted.

5. Using both hands, mold nose-clip to the shape of the lower part of the nose to ensure a close fit and good seal. Pinching the nose-clip using only one hand may result in less effective respirator performance.

6. The seal of the respirator on the face should be fit-checked before entering the workplace.

7. Do not alter, modify, clean or repair this respirator.

8. Dispose in accordance with local regulations.

9. Store in accordance with manufacturer’s instructions.

10. Storage temperature should be between -20°C and +25 °C.

11. Storage humidity should be less than 80%.

12. When storing or transporting this respirator use original packaging provided.

13. Do not store in direct sunlight.

There are three equipment classes: FFP1/FFP2/FFP3 (See marking on box and on mask). For the particle filtering half mask marked “NR”, it shall not be used for more than one shift.

These respirators are approved by INSPEC, and audited annually by ICR Polska Co. Ltd.

These respirators are CE Marked to the requirements of Community Directive 89/686/EEC or European Regulation (EU) 2016/425. The applicable legislation can be determined by reviewing the Certificate and Declaration of Conformity at https://www.acewiper..com/

ICR Polska Co. Ltd. (NB 2703) Plac Przymierza 6 03-944 Warszawa , Poland.

Phone: 0086769-82329088, 0086769-82329188

Mobile phone: 0086+13580992809

Email: sales@acewiper.com

Address: Jinma Road, Shiyong Industrial Zone, Shiyong Village, Hengli Town, Dongguan City

| |

| Scan code consulting |